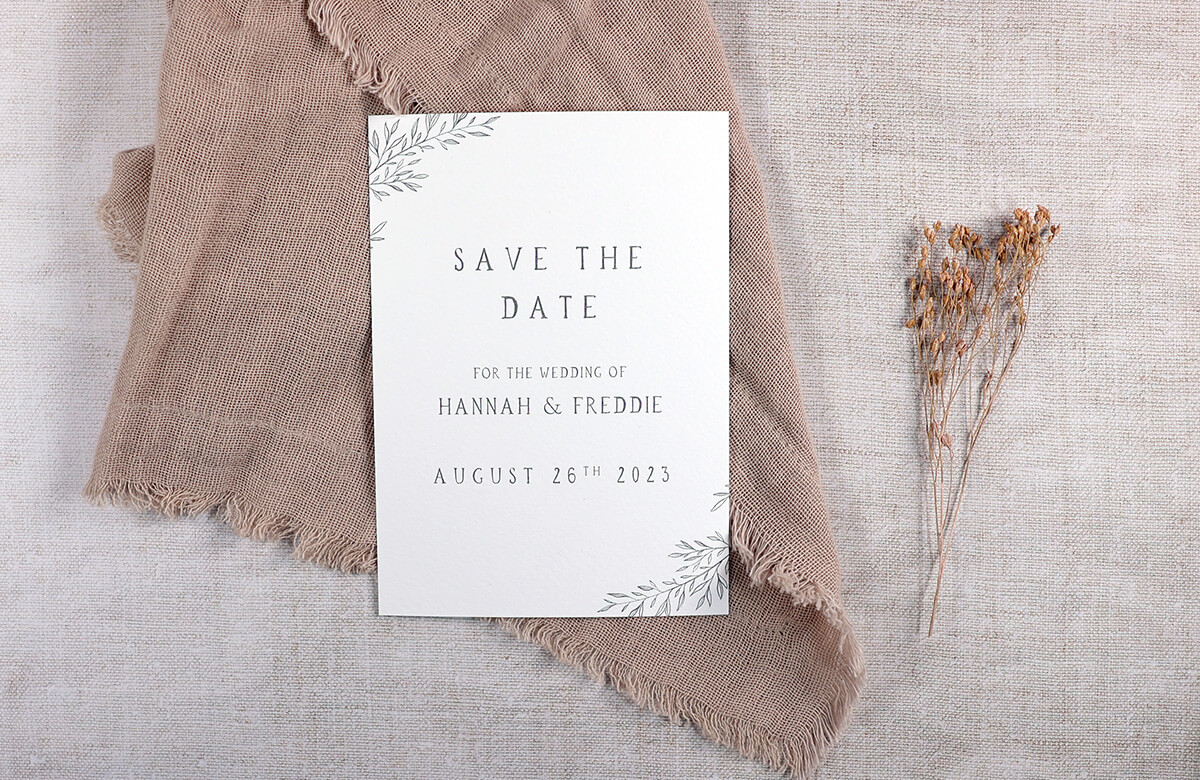

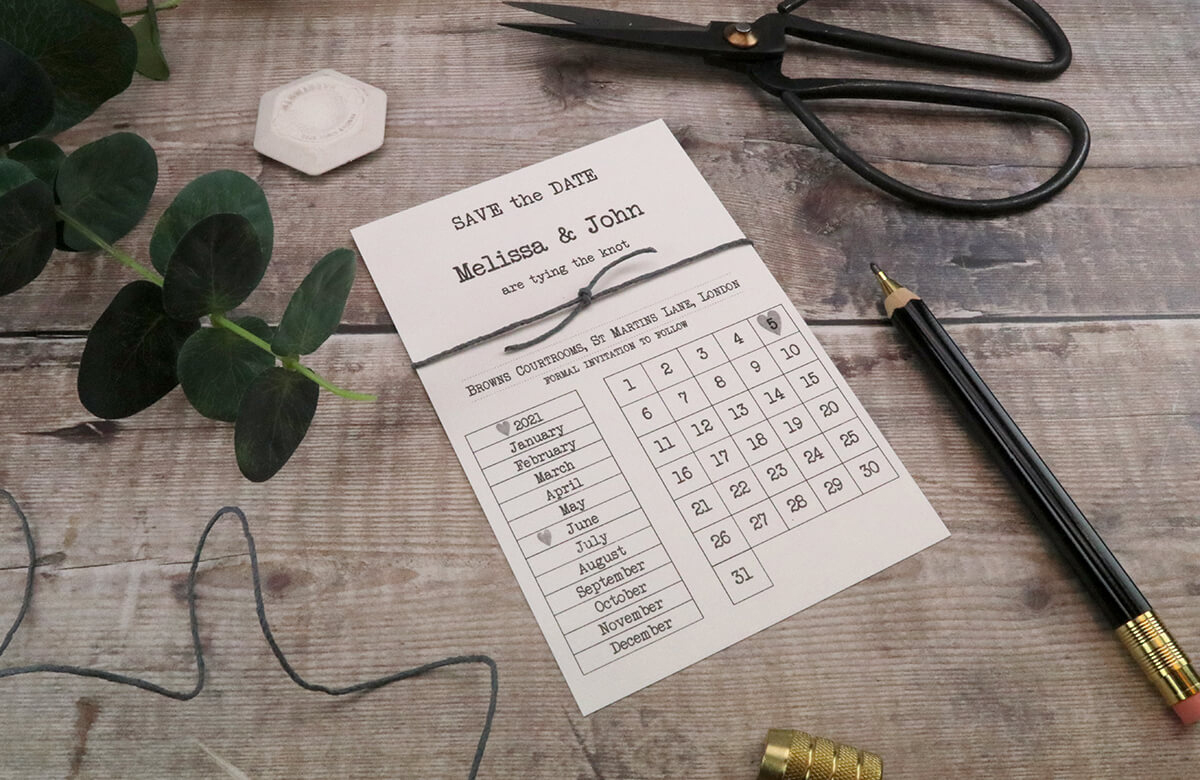

Rustic Wedding Invitation Ideas Rustic wedding invitations are the perfect choice for couples who want a look that is down-to-earth, romantic, and timeless. Rustic wedding invitations convey a sense of warmth and comfort, making them suitable for all types of weddings, from beachside ceremonies to rustic barn weddings. We have lots of inspiration for you. […]

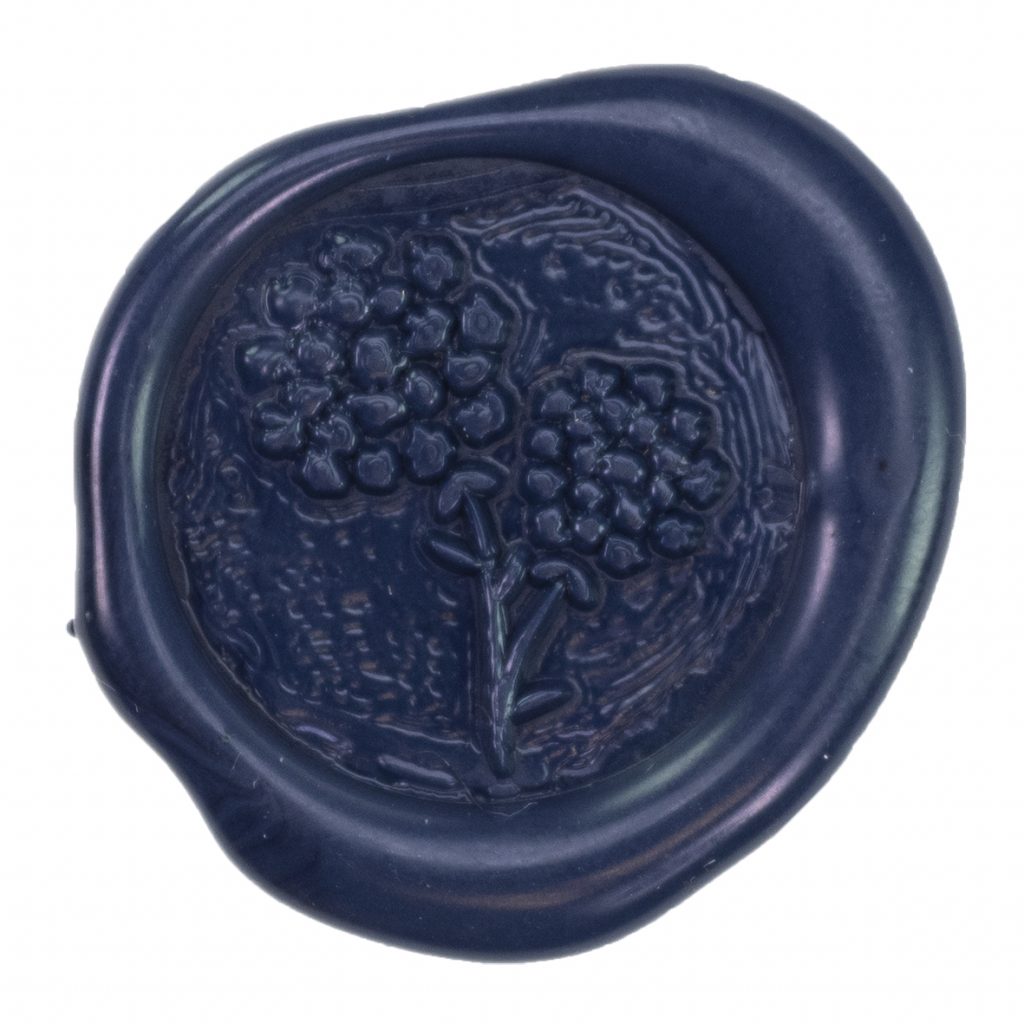

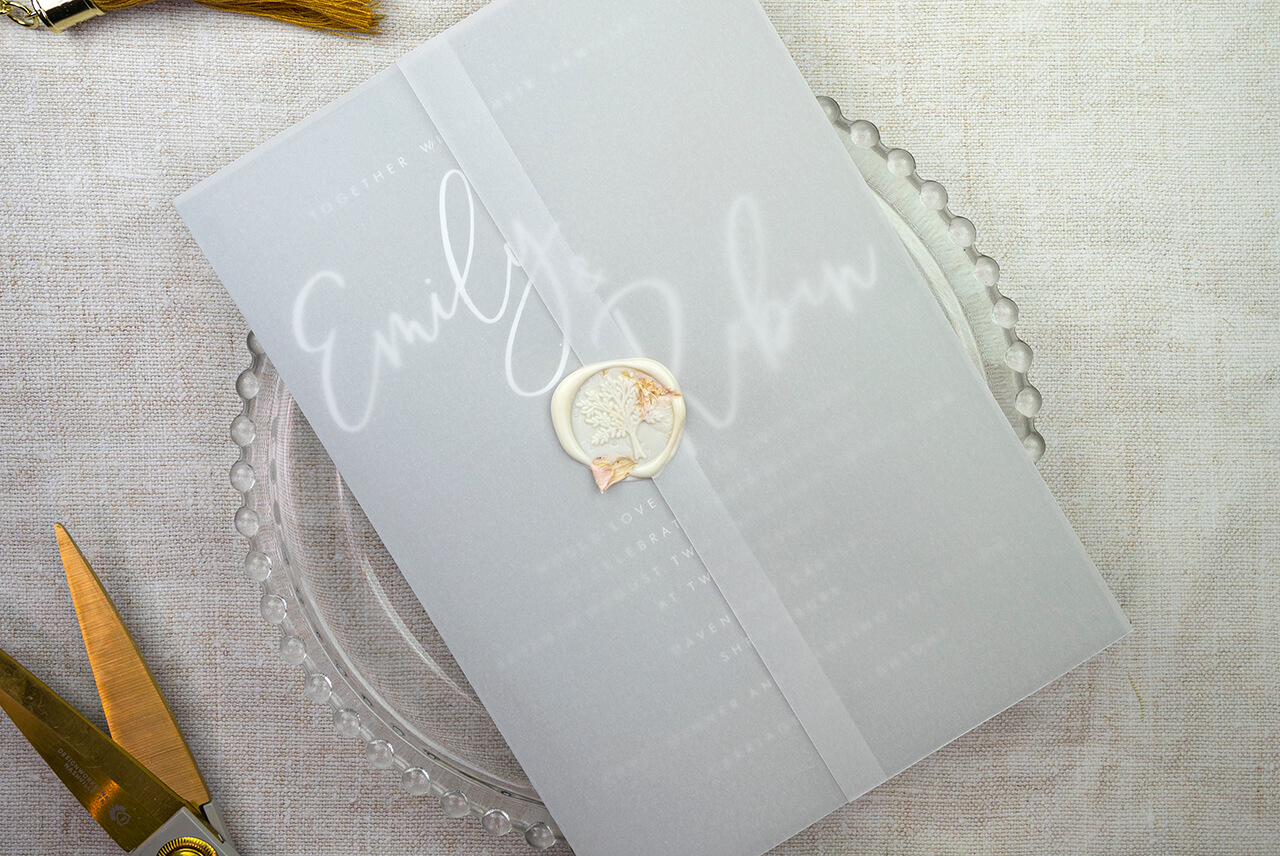

The art of wax seals has existed for centuries. We have a beautiful selection of sealing wax and stamps that can be used for wedding invitations and lots of inspiration to inspire you.

What is a Wax Seal Used For?

Wax seals are used today for sealing wedding invitations, letters and important documents. They provide a unique and elegant way to deliver important letters and legal documents. They add an extra layer of security as when the recipient breaks the seal; they know they're the first and only one to have opened the letter by breaking the seal.

Why Did People Stop Using Wax Seals?

Wax seals lost their appeal because the newly invented adhesive stamp meant that there was a faster, more efficient way to seal documents. Wax seals also require specific tools and can be labour-intensive and time-consuming. Since they're are not so relevant today, they have become more of an aesthetic choice or a way to add personal style to correspondence. However, wax seals may still be used for legal or official documents due to their traditional association with trustworthiness.

Nowadays, seals are most often used as decorative items for stationery, invitations, correspondence and decorating gifts.

Types and Categories of Sealing Wax

There are many different types of sealing wax that can be used for wedding invitations and envelope seals. Some of the most popular types of sealing wax include beeswax, carnauba wax, and resin-based waxes. You can use normal candle wax but you may find it difficult to get a good seal, and it tends not to stick to the paper well.

Traditional waxes are rolled into sticks with or without wicks. The most convenient is our glue gun sealing wax which can quickly and easily be melted with a glue gun. Traditional sticks with wicks sometimes create soot which can drop into the wax and it's not so efficient to make lots in one go.

Can You Use any Type Of Wax for Wax Seals?

While it is possible to use normal candle wax, it's not easy for it to work correctly and get a good seal, also the wax may not so easily stick to your paper or cards. It is best to use sealing wax specifically designed for the process, such as beeswax, carnauba wax or resin-based waxes.

You can make wax seals directly on the envelope or paper or make them on silicone or a baking sheet, let them cool and use them later. By attaching an adhesive disc to the back, you can make your own self adhesive wax seals.

The main benefit of using a silicone sheet is that non-perfect ones can be remelted and reused.

Self Adhesive Wax Seals

You can make seals directly on the envelope or paper or make them on silicone or a baking sheet, let them cool and use them later. By attaching an adhesive disc to the back, you can make your own self adhesive wax seals.

The main benefit of using a silicone sheet is that non-perfect ones can be remelted and reused., if you're not happy with the shape.

Choosing a Stamp for Wax Seal Stamping

Our selection of stamps and sealing wax stampers include a variety of designs that are perfect for adding a unique and personal touch to your invitations.

Whether you're looking for a simple design or something more elaborate, we have a wax seal stamp that's perfect for you. Popular designs include text, monograms, initials and logos.

Text designs are simple and elegant. Monograms can be unique and personal, while logos can be used for corporate, marketing or business branding. They're ideal for Etsy sellers that sells a select range of high-end handmade items and gifts.

Sealing Wax Shades

Many different shades of sealing wax colour can be used for invitations, and you can also melt colours together to create your own colour.

When shopping online remember that each batch of wax is mixed by hand so there will be shade variations.

What Does a Black Seal Mean?

A black seal typically symbolises authority, power, and strength. It is often used to represent a person of high status or wealth. Historically, it has been used to close letters or documents representing important matters related to business or government affairs and it can also be a sign of protection for messages in times of danger.

How to Make Wax Seals

Making seals is easy with our sealing wax. All you need is a low temperature glue gun and some patience.

To get started, melt the sealing wax in your glue gun. Once it's melted, carefully apply it to your letters, envelopes or invitations. Then, press the stamp into the wax on your paper or envelope. Hold the stamp in place for a few seconds to allow the wax to cool and set. When cooled, your seal is complete!

Making seals is a great way to add a personal touch to your wedding invitations. It's easy to create beautiful, custom seals that will make your invitations stand out from the crowd.

Your bespoke stamp can be used repeatedly, so even after the big day, you can create beautiful personalised stationery.

Wax Seals and Production

When you have lots of seals to make the easiest method is to set up a production line using glue gun sealing wax and a silicone mat. You can use an ice pack to cool the stamp every one or two wax seals (make sure the stamp isn't icy cold, as this can create unwanted icy patterns in the wax).

Cleaning your Glue Gun

Remember that you'll aways need some clear wax (or even glue) to purge and clean your glue gun after use.

Browse or search our online store to order, and don't hesitate to contact us if you need advice or more information on delivery details. Finally remember making wax seals is lots of fun and can be quite addictive!

The Art of Wax Seals The art of wax seals has existed for centuries. We have a beautiful selection of sealing wax and stamps that can be used for wedding invitations and lots of inspiration to inspire you. What is a Wax Seal Used For? Wax seals are used today for sealing wedding invitations, letters […]

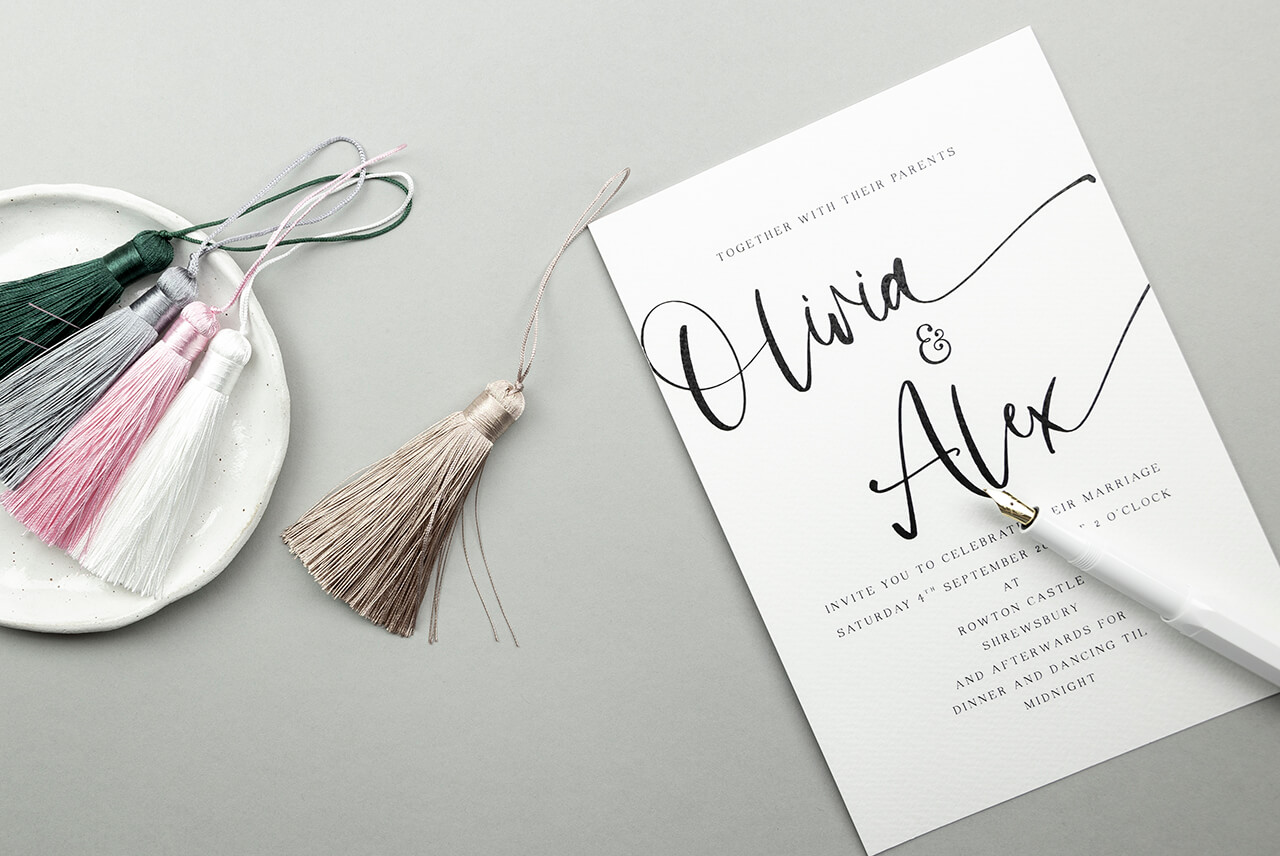

Choosing Perfect Wedding Invitations As you search for the perfect wedding invitation, your individual style should be at the forefront of it all in order to make a lasting impression on your big day. With endless options around every corner, selecting just one can become quite daunting; this guide will provide you with plenty of […]

Peach Fuzz – Pantone Colour of the Year 2024 This year, Peach Fuzz has been unveiled as the Pantone colour of the year, and wedding season is abuzz with talk of how the trend will translate to the aisle. For brides and wedding stationers, this hue represents a delightful opportunity to create invitations that not […]

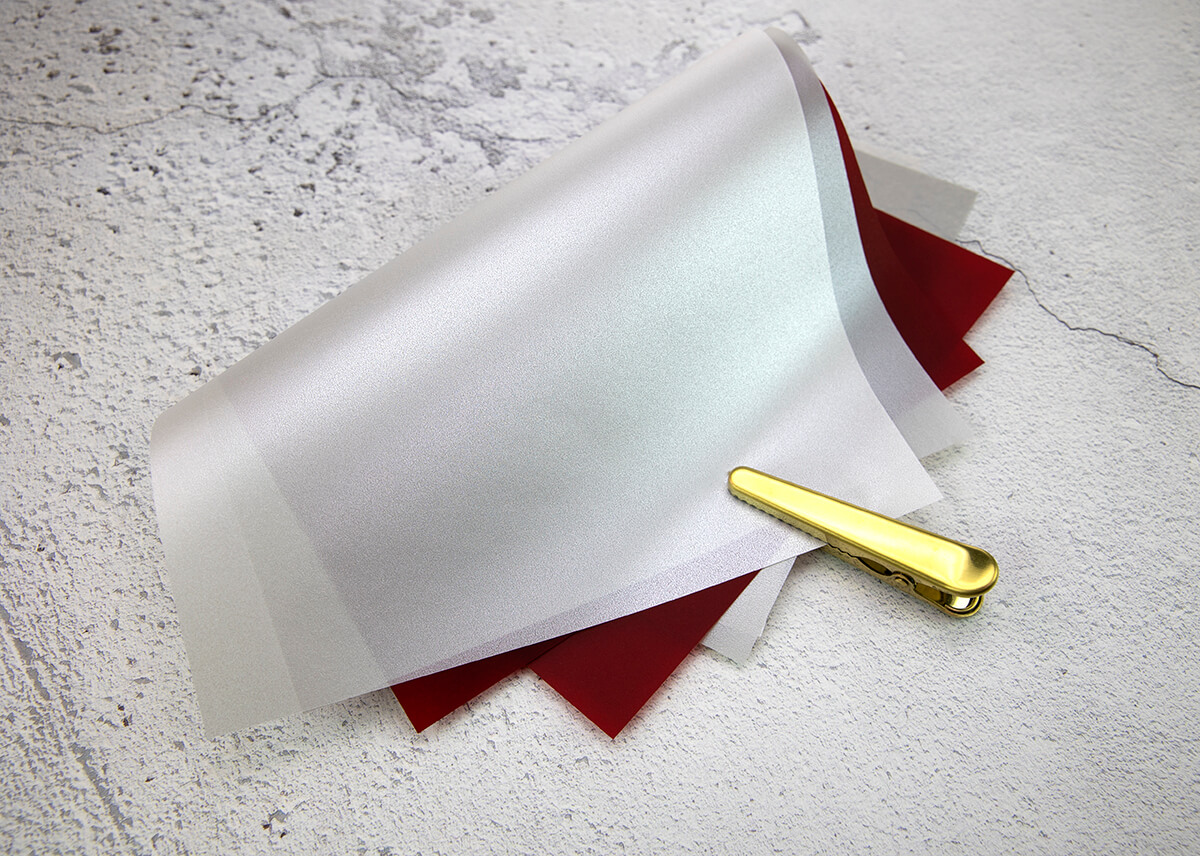

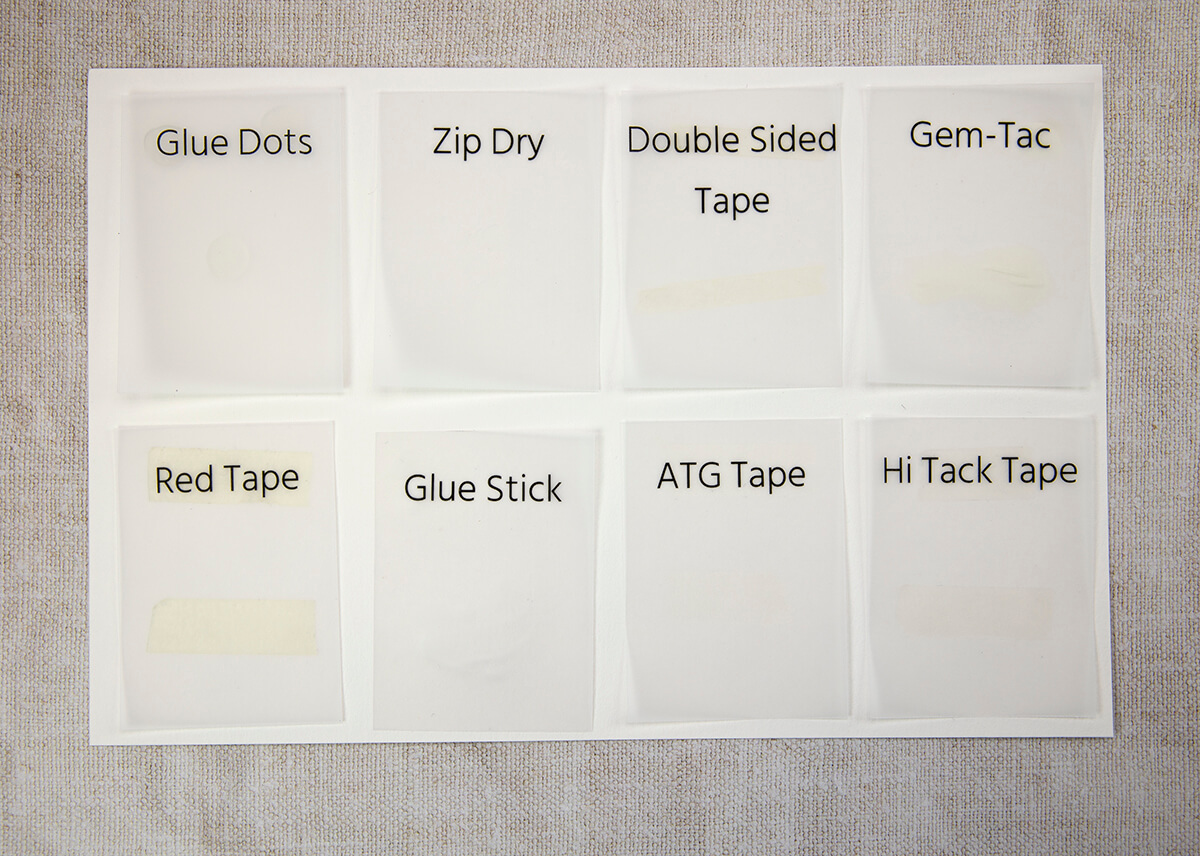

Say hello to our new coloured vellum papers which perfectly complement our A3 and A4 vellum papers. With a wealth of experience as wedding stationers ourselves, we’ve used this beautiful paper for many years and understand how it can be used and add a sense of luxury to your wedding invitations. So we’ve included lots […]

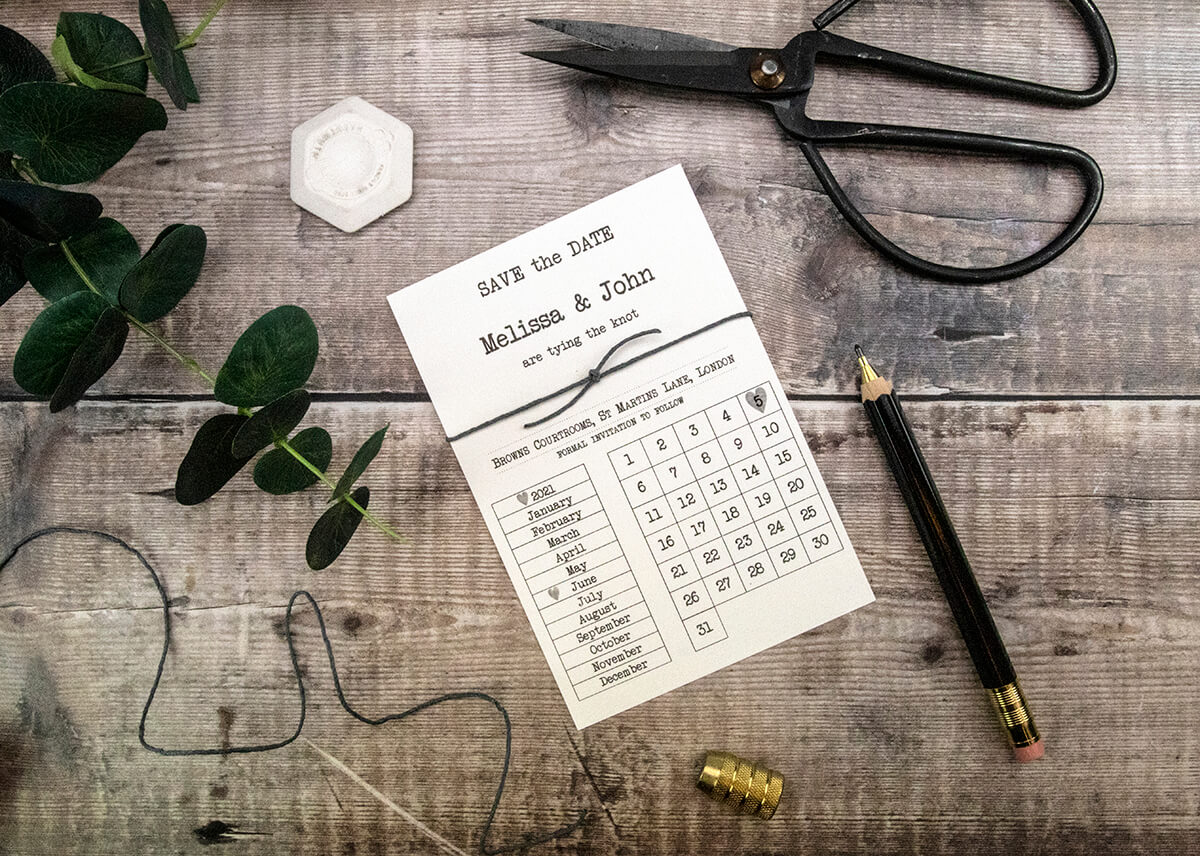

With lots of newly engaged couples after Christmas and New Year and exciting proposals planned for Valentine’s Day, many will be taking their first steps into wedding planning in the coming months. So now is the time to start planning your wedding if you’re newly engaged. It’s an exciting time so enjoy it! Use our […]

Wedding favours are a great way to show your appreciation for your guests. They’re also a fun way to personalise your wedding. Here are some ideas on how to create your own wedding favours. Guests will love homemade DIY wedding favours from the bride and groom on the wedding day. What’s more, as they can […]

Create a unique and elegant laser cut wedding invitation that stands out from the crowd in style and design. This tutorial shows how to create a simple yet elegant invitation using our Baroque blank laser cut wedding invitation. It’s easy to alter the colours if pink doesn’t match your theme, you can choose a different […]

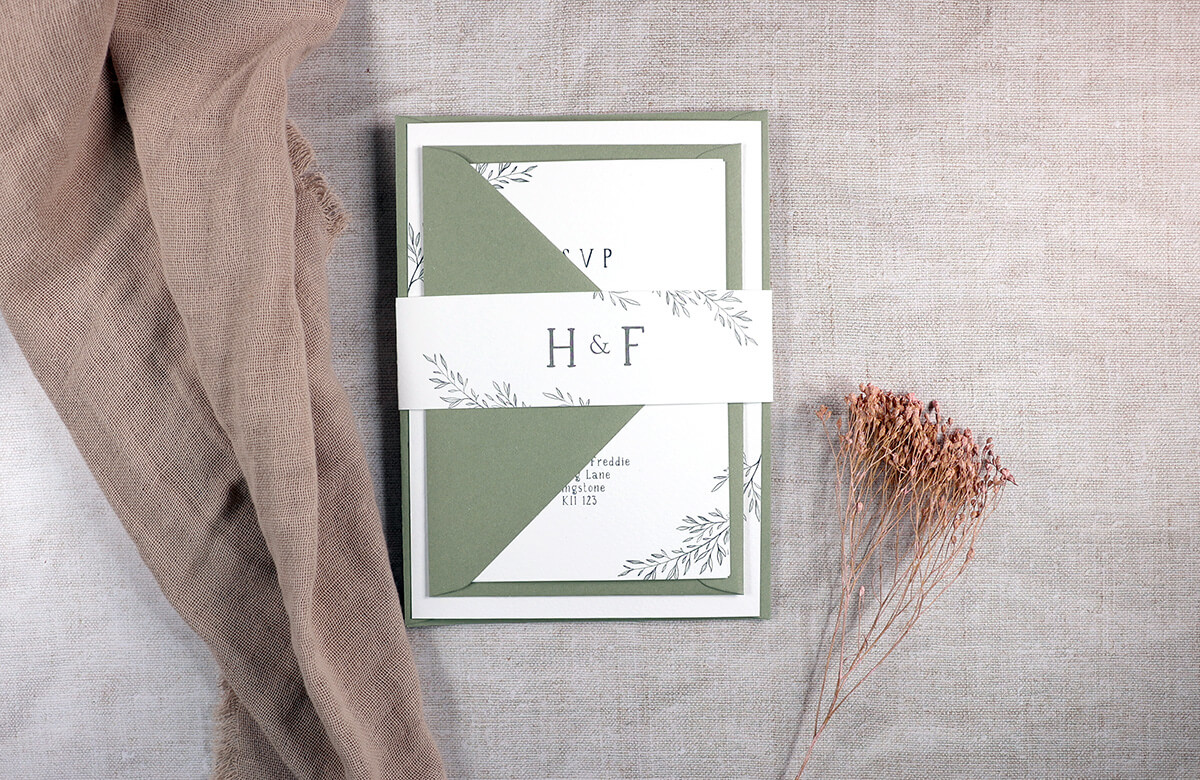

One of the most popular styles of DIY wedding invitation designs is the pocketfold invite. Pocketfold wedding invitations are popular because they neatly store the invitation and the enclosures such as the RSVP card together. The style can be adapted to your wedding whether you’re looking for rustic wedding invitations, a vintage style or even […]

If you love pocketfold invites but also love the intricate nature of a laser cut wedding invitations, then this design is perfect for you. Our Baroque Pocketfold laser-cut wedding invitations combine all the functionality of a pocketfold but with the beauty of an intricate laser cut invitation. For DIY laser cut wedding invitations, they can […]